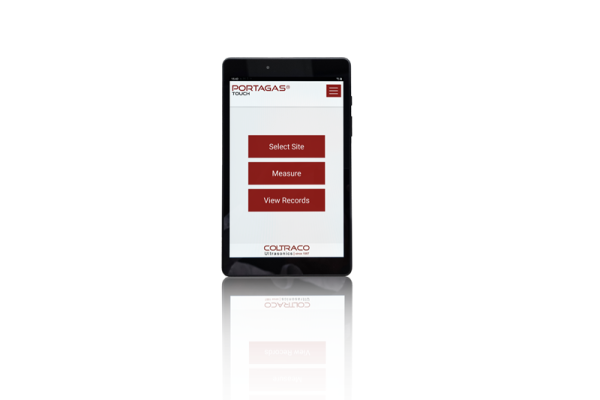

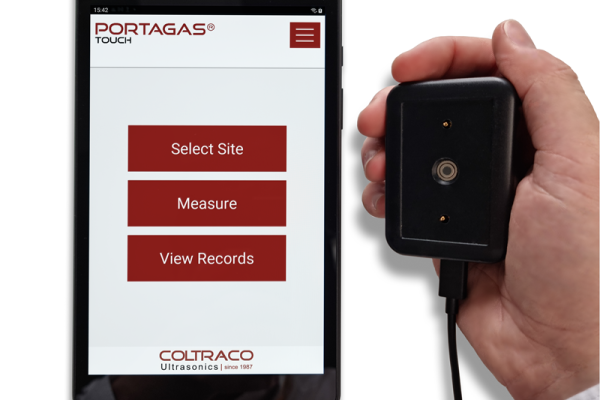

Portagas® is a world’s first technology for non-invasive, non-destructive monitoring of pressurised, inert gas systems.

It is a unique and innovative solution designed to monitor the pressure of pressurized, non-liquefied inert gases and compressed gas cylinders, including Inergen®, Nitrogen, Oxygen and Argon.

Utilizing sophisticated signal processing and acoustic technology to detect even minor fluctuations in internal cylinder pressure, with precision below the 5% required by regulations, making it a valuable tool for ensuring safety and compliance.

P/N: 3107505-GAS

CAGE Code: KD983 – COLTRACO LIMITED